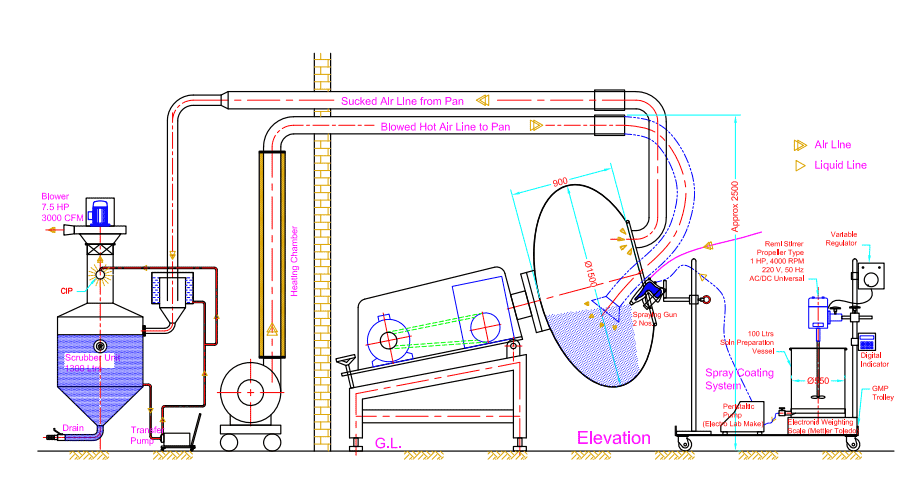

Coating system

Coating Pan System consist of

1)Coating Pan mounted on a drive unit resting on a SS round pipe stand ensuring lesser dust accumulation.

2)Suction Blower, Heating Chamber, SS pipeline from Suction Blower to Coating Pan for blowing hot air to Coating Pan ensuring proper drying of Coated Tablets.

3)Scrubber Unit with suitable Suction Blower & Water Transfer Pump which ensures proper sucking of colored particle fumes from coating pan and thereby ensuring trapping of these particles & preventing them to resettle on the tablets & coating area.

4)Spray Coating System: It consist of Solution Preparation Vessel with Electronic Weighing Scale, Peristaltic Pump, Variable Frequency Drive, Propeller Type Stirrer, Digital Indicator and Spray Gun with Stand. This ensures thorough Spray Coating on Tablets moving in the Coating Pan.

- Facility of angular adjustment of Coating Pan facilitates the perfect angle for Coating different products.

- Well Designed Spray Coating System ensures uniform Spraying of Coating Liquid thereby increasing Tablet Coating Quality & efficiency.

- Contact Parts SS 316

- Flame Proof Electricals.

- Variable Frequency Drive for controlling Coating Pan Speed(3 to 30 RPM)

- Provision of Scrubber Unit ensures proper trapping & removal of uncoated colored particles thereby reducing its chances of settling on the tablets or spreading on the walls of coating area & outside surface of Coating pan.

- Internal Surface Polish to be mirror finish 240 grid, External to be 180 grid dull finish.

- As Hot Air Blower & Suction Blower with Scrubber unit are installed in service area, Production Area remains neat & clean.

Extra features: PLC Control Panel

Available Sizes: 12",24",30", 36", 48",60",72" dia.