Manufacturing Vessel

Italco Pharma is engaged in the manufacture of Manufacturing Vessel

In the pharmaceutical industry, the Manufacturing Vessel is used to prepare injections, small volume medications, sterile medications, and inhalers.

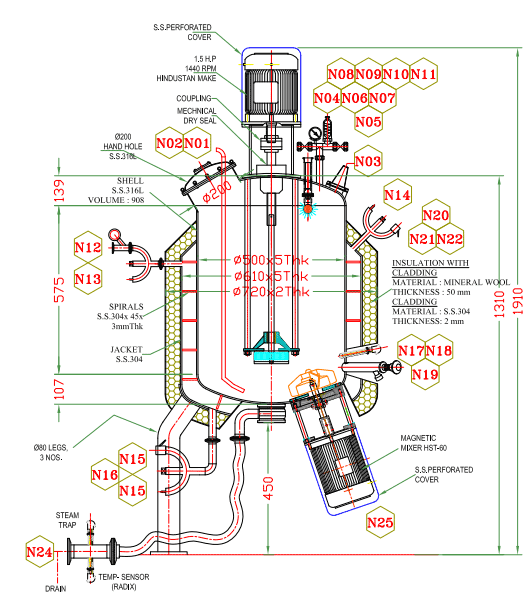

Structure of Manufacturing Vessel :

The sterile manufacturing vessel is produced having a dish-shaped top and bottom. The top of the vessel has a silicone gasket and flanged ends.

A stirrer having an electric motor is connected to the sterile Manufacturing vessel. The speed of the machine is controlled by variable frequency drive mounted on the top dish The stirrer has a single cartridge with the seal of dry carbon. The whole structure of Manufacturing vessel is placed on the pipe legs with castors having PU wheels and SS brackets.

The Manufacturing vessel also has an electro-polished inner surface and an entry magnetic stirrer at the bottom. The Manufacturing vessel comes has jacket of stainless-steel and have the options of steam or electrical heating and cooling. The sterile vessel is covered with welded stainless-steel sheets and wrapped with mineral wool.

The Manufacturing vessel comes with different accessories made for different

- Manufacturing Vessel (With Load cell & Magnetic Starrier) - (100 Ltrs to 1000 Ltrs)

- Pressure Vessel - (50 Ltrs to 300 Ltrs)

- Filling Vessel - (50 Ltrs to 300 Ltrs)

- Membrane Filter - 142 & 293 Model