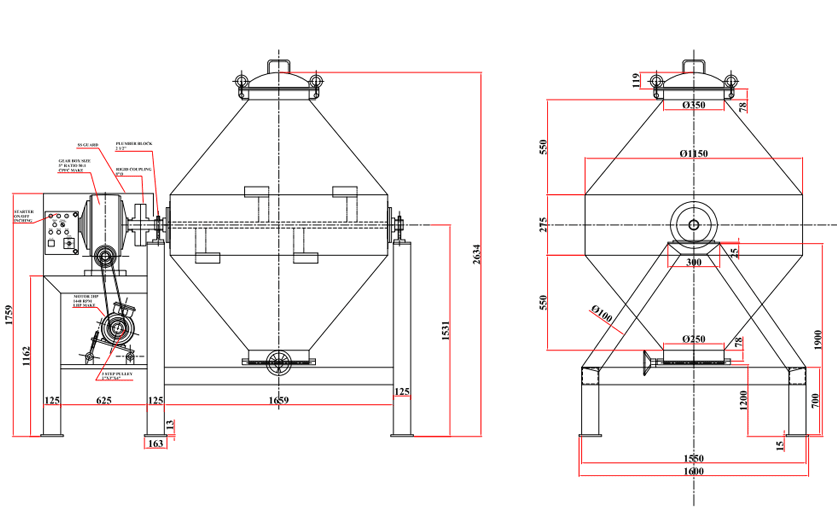

Double Cone Blender

Italco Pharma is engaged in the manufacturing of Double Cone Blenders.

Double Cone Blender is an efficient and versatile machine for mixing of dry powders and granules homogeneously. All the connecting parts are made from stainless steel. The beneficial volume for excellent homogeneity is between 35-70% of gross volume. The SLANT double cone design eliminates dead spots

Double Cone blenders Application & Process :

Nutraceutical, Pharmaceutical, Food, cosmetics, Chemical, pesticide, , ceramics, plastics, and other Allied industries.

The Double Cone blenders are comprised of long two corner of product container to give maximum rubbing and tumbler effect to the material and also for fast and homogenizing mixing. Double shape blenders can produce equivalent dry mixing of granules, free flowing powders needed for low shearing force, Mixing and combining of particles with fast intermixing of particles regardless of varying specific gravities. The material is stocked into the double cone blender drum. The double blender is tumbling the material in the container and spread out. The mixing is gained in the span of 5 to 15 minutes with better homogeneity.

- Consistent Mixing with paddle blade stirrer.

- The conical shape at both ends helps in equal mixing and easy discharge

- The cone is meticulously balanced to circumvent additional load on the gear box and motor

- The powder can be released through a butterfly or slide valve even when it can be filled into the cone through a wider opening.

- Depending upon the product, paddle-type baffles can be provided on the shaft for better mixing inside the cone.

- The fluid bed drying technique is ideal for the fast, even drying of pharmaceutical, chemical, and food product.

- The material may be in form of granules, powder, or crystals.

- Ideal initial moisture content should be up to 20%, but even the materials with higher initial moisture content can be dried successfully.