Starch Paste Kettle

Italco Pharma is engaged in the manufacture of Starch Paste Kettle.

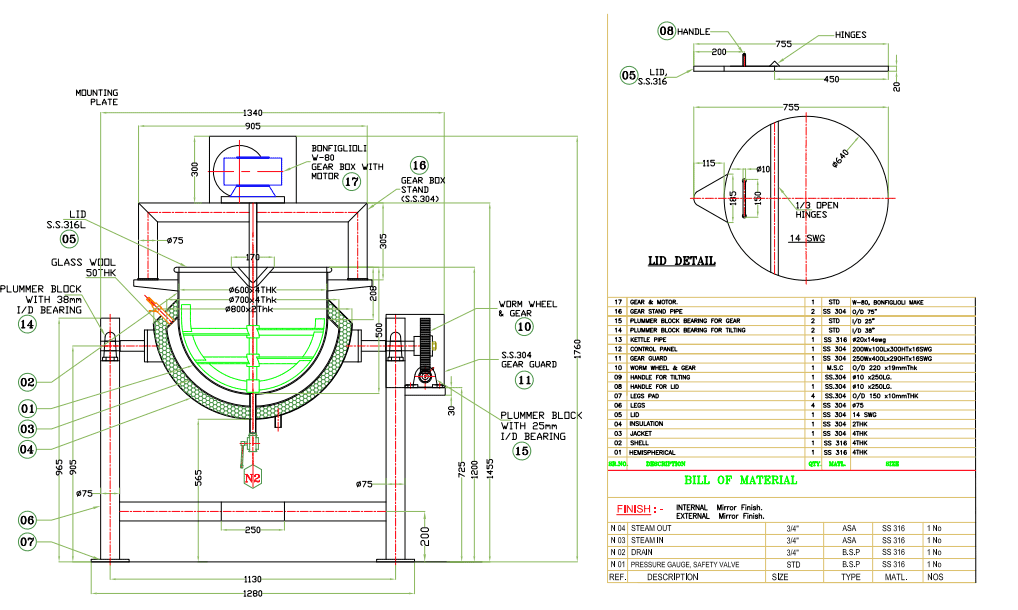

Starch Paste Preparation Kettle also known as Binder Preparation Vessels (Paste Kettle) is used for making Starch Paste. The Conical Shape of Starch Paste Kettle makes certain that the Heating of Starch Paste is constant and have more surface area. Paste Kettle with Tilting Arrangement is use for unloading of the Paste into the Vessel or Container.

Starch Paste Kettle manufactured by Italco Pharma are particularly designed for pharmaceutical applications. Starch Paste Kettle is used for making of binder materials which are broadly used in medicine and food industries. Quick and balanced heating with systematic stirring verifies superior quality of starch paste in least amount of time.

Structure of Starch Paste Kettle :

Starch Paste Kettle machine has an electrically heated jacket, which removes the requirement of providing a steam connection for heating. Starch Paste Kettle also terminates the requirement to empty the contents the vessel by arranging an outlet valve at the bottom of the hemispherical vessel that can unload the content directly into containers which can be kept below it. This enables the operators to handle the hot starch paste in a much safer way.

- Hemispherical design for proper mixing paste

- Jacket provided with Steam/ Thermic/ Fluid heating arrangement

- Tilting arrangement for kettle is provided for discharge for starch paste

- Safe earthing system

- Top drive with German make gear box

- The fluid bed drying technique is ideal for the fast, even drying of pharmaceutical, chemical, and food product.

- The material may be in form of granules, powder, or crystals.

- Ideal initial moisture content should be up to 20%, but even the materials with higher initial moisture content can be dried successfully.